Various biogas production system

The Department of Alternative Energy Development and Efficiency (DEDE) promotes biogas production from elephant dung, the prototype development and demonstration project for usage of instant or semi-instant animal waste to produce biogas, and the promotion of biogas production from industrial waste water.

Thailand has been promoting biogas production for over 20 years. At the initial stage, the promotion is limited only to household or retail farmer level. The DEDE is now promoting biogas production from elephant dung, the prototype development and demonstration project for usage of instant or semi-instant animal waste to produce biogas, and the promotion of biogas production from industrial waste water with details as follow:

1.The biogas production from elephant dung is the project that is initiated in honor of His Majesty the King to demonstrate the use of alternative energy at the Royal Elephant Stable and common elephant stable at the Thai Elephant Conservation Center in Hang chat district of the Lampang province. It has installed one 50 cubic meter system and one 100 cubic meter system to produce biogas from elephant dung at the Royal Elephant Stable and two 100 cubic meter systems at the common elephant stable at the Thai Elephant Conservation Center. It has also established seven prototype systems for six private elephant stables including two systems for the Pattaya Elephant Village in Nong prue, Chonburi; one system for the Pattaya Elephant Camp in Sattahip, Chonburi; one system for the Tin Chang Thai in Nong Prue, Chonburi; one system for Hua Hin Elephant Stable in Huahin, Prachuabkirikhan; one system for Taweechai Elephant Stable in Kanchanaburi, and one system for Home Stay of the Thai Elephant Conservation Center in Lampang.

Figure 1 Biogas production from elephant dung

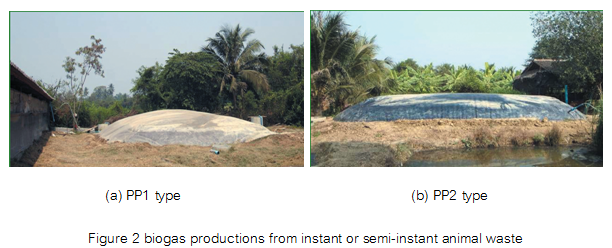

2. The DEDE has studied four types of prototype development and demonstration project for usage of instant or semi-instant animal waste to produce biogas and has chosen only two types for further development including:

1. PP1 type (Paya Ngew Dam) suits for farms that generate no less than 10 cubic meters/day of waste water, equivalent to 500 fattening pigs, with 70 cubic meters digester and biogas output of 17.3 cubic meters/day. The DEDE provides 50% subsidy of the THB186,480 total investment cost.

2.PP2 type (Tanee 1) suits for farms that generate no less than two cubic meters/day of waste water, with 13 cubic meters digester and biogas output of 5.3 cubic meters/day. The DEDE provides 72% subsidy of the THB130,868 total investment cost.

In the fiscal year 2012, the DEDE subsidized a total of 43 farms, comprising 18 PP1 type and 25 PP2 type. They consist of 28 pig farms, two buffalo farms, one horse farm, one partridge farm, and 11 cow farms.

3. Biogas production from industrial waste water promotion project to demonstrate system installation at four potential industrial plants, with no less than 1,500 mg/liter COD value and adequate waste water to produce at least 3,000 cubic meters/day of biogas. These plants are capable of producing 41,502 cubic meters/day, or 13,695,660 cubic meters/year of biogas. They are:

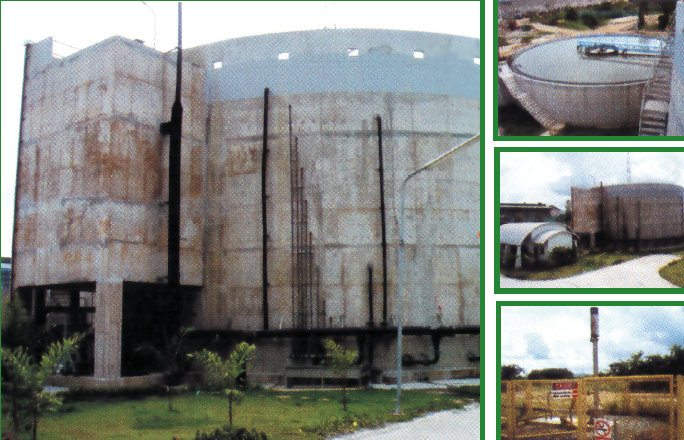

1.Thai Paper Mill Ltd., a paper manufacturing plant in Rayong that generates 7,000 cubic meters/day waste water (20 cubic meters/ton of output). It has installed the UASB (Upflow Anaerobic Sludge Blanket) biogas production system from waste water. It produces 3,472 cubic meters/day of biogas to be used in conjunction with wood waste as fuel and can substitute 7.25% of wood waste, saving THB1.97 million/year (340 working days/year). The DEDE provides THB6.22 million subsidy for the THB48.6 million construction costs of the biogas production and waste water treatment systems.

Figure 3 Thai Paper Mill Ltd.’s biogas production and water treatment systems

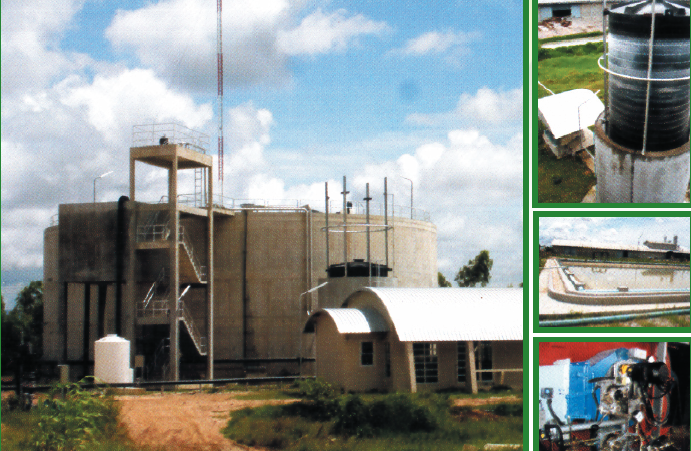

2. Iamburapa Ltd., a tapioca flour manufacturer in Sra Gaew with production capacity of 250 tons/day and 4,000 cubic meters/day waste water generation. It has installed UASB (Upflow Anaerobic Sludge Blanket) biogas production system from waste water. It produces 14,790 cubic meters/day of biogas to be used as fuel for its burner that can substitute 8,000 liters/day of fuel oil, saving THB32.27 million/year. The DEDE provides THB6.22 million subsidy for the THB50.83 million construction costs of the biogas production and waste water treatment systems.

Figure 4 Iamburapa Ltd.’s biogas production and water treatment systems

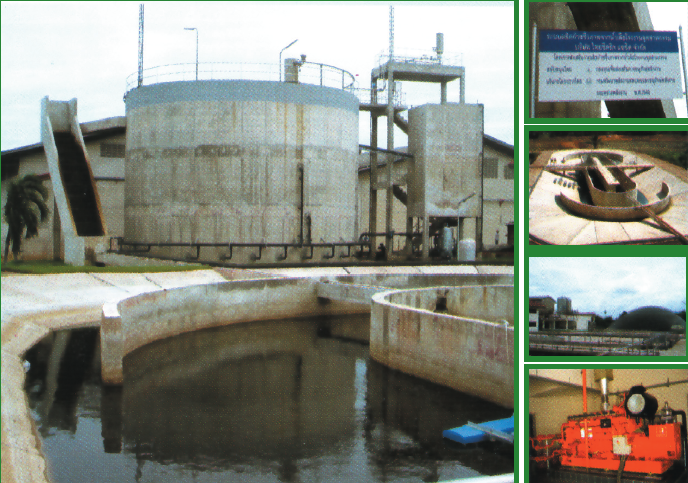

3.Thai Citric Acid Ltd., a citric acid manufacturer in Samutsakorn with production capacity of 24 tons/day. It has installed UASB (Upflow Anaerobic Sludge Blanket) biogas production system from waste water that can accommodate 600 cubic meters/day of waste water. It produces 3,240 cubic meters/day of biogas that fuels the production of 5,184 kilowatt-hour/day electricity for the plant, saving THB4.25 million/year in power bills. The DEDE provides THB6.22 million subsidy for the THB47.37 million construction costs of the biogas production and waste water treatment systems.

Figure 5 Thai Citric Acid Ltd.’s biogas production and water treatment systems

4. I-san Tapioca Flour Ltd., a tapioca flour manufacturer in Nakornratchasima with production capacity of 350 tons/day and 5,000 cubic meters/day waste water generation. It has installed HRAL (High Rate Anaerobic Lagoon) biogas production system from waste water. It produces 20,000 cubic meters/day of biogas to be used as fuel for its burner that can substitute 12,000 liters/day of fuel oil, saving THB50.4 million/year. The DEDE provides THB6.22 million subsidy for the THB40.66 million construction costs of the biogas production and waste water treatment systems.

Figure 6 I-san Tapioca Flour Ltd.’s biogas production and water treatment systems

| Attachment | Size |

|---|---|

| 561.92 KB |